Liquid Phase Catalytic Exchange (LPCE) Columns

CECE Suited: Design to operate with an Electrolysis cell as a combined electrolysis and catalytic exchange system

Efficient Water flow: Internal water re-distribution system removes edge channeling

Efficient Packing: Random packed catalyst, Inert and hydrophilic stainless raschig rings allows for high molar ratio of gas to liquid

Tritium compatible: Full Stainless-Steel construction, high leak tightness

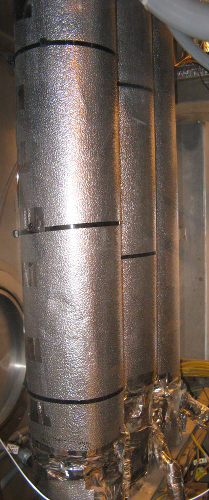

The Liquid Phase Catalytic Exchange (LPCE) column is fully integrated and ideally suited for Combined Electrolysis and Catalytic Exchange (CECE) systems. The column is a plug and play design with all necessary fittings, heaters, thermocouples, connectors, insulation and protective casings included for a fast and easy modular installation. A variety of unique and proprietary concepts ensure that the Torion LPCE column can operate at maximum efficiency. The column diameter and length are variable and selected to meet specific applications.

The Torion LPCE column design has addressed the gas and water flow distribution using a proprietary distribution system that is scalable from 1” to 12” in diameter. This system ensures uniform water coverage of the catalyst and minimizes channeling and dead zones for either water or gas. This unique system allows the LPCE columns to operate at high molar fluxes and molar ratios for any column diameter.

The Torion LPCE column has been designed to minimize tritium hang up inside the column. All internal surfaces use surface roughness less than 20 µinch RMS to ensure the columns can quickly recover from high activity operations.

Design Benefits

A proprietary catalyst mixing of wet proof catalyst with other materials provides an efficient isotopic exchange environment within the column with impressive height-equivalent-theoretical plates (HETP) at optimal operating conditions. The column is designed to be operated from 20 oC to 80 oC, pressures ranging from 100 mbar to 2,000 mbar and molar fluxes from 5 to 80 mol/m2/s to provide a wide range of operation. The columns and attendant fittings are designed and tested to ensure the leak rate of each fitting is below 1*10-9 atm-cc/s when the upstream side is exposed to one atmosphere of helium.

Brochure – LPCE Columns

Download the pdf for details