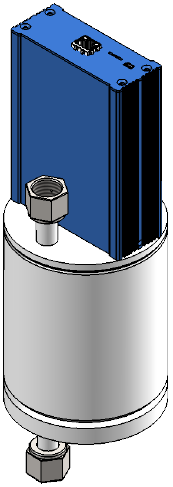

iTM 1L Tritium Process Monitor

Ionization chamber, preamplifier and controller in one small package

Auto range across 6 decades of signal

Multiple chamber sizes and designs to fit the need. Custom sizes as well

Single Ethernet connection provides power and signal

Registered to ASME Section VIII Div 1

The internet enabled Tritium process monitor (iTM) are in-line registered pressure vessel ionization chambers with preamplifier, multi-range controller, and power all integrated into a single compact design.

The iTM has only one RJ-45 ethernet jack that provides all required voltages with the power over ethernet (POE) protocol and all communication over the ethernet. Connectivity to multiple iTM’s only requires a POE switch or router connected to your data acquisition (DAQ) or computers local area network (LAN).

A variety of standard or custom-made ionization chambers with detection volumes from 1 cc to 1000 cc using both solid and wire walls allow for maximum flexibility when designing a tritium detector for your process needs.

The integrated four stage multi-ranging capability provides 6 decades of measurement range. The iTM can be operated in an auto ranging or manual ranging mode.

The integrated POE electronics do not have external controller which reduces glovebox penetration requirements. Multiple iTM’s can operate off a single switch installed inside the glovebox with a single RJ-45 ethernet cable penetration.

Design Benefits

The iTM is designed for use as an in-line process monitor. All ionization chambers are registered pressure vessels to comply with the process pressure envelope. The units are helium leak tight to 1×10-9 scc/sec at the operating temperatures as high as 150oC. All units come standard with ½” VCR8 female fittings to provide leak tight installation.

Brochure – iTM 1L Tritium Process Monitor

Download the pdf for details